AR automatic backwash filters

Your current position:HomeProductAR automatic backwash filters

Tel:+86.21 51097921/51090930

Manager Li:13306264360

Technical Support:Mr. Feng 15216602964

Email:jci_sales@163.com

Factory address: 368 Qinggao Road, Fengxian District, Shanghai

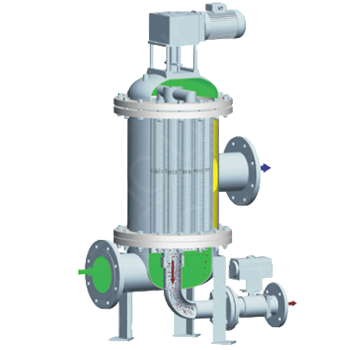

Filtering process

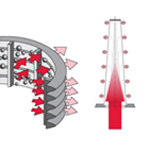

Liquid flows into the filter via the inlet and then flows through the internal surface of filter screen and goes out from the outlet. Impurities are intercepted on the inner surface of the filter screen and the filter cake slowly accumulates which leads to gradually pressure drop increasing between the inlet and outlet. The flux of the filter screen becomes lower.

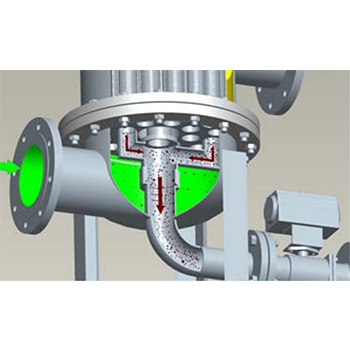

Back-flushing process

When it reaches the preset pressure drop or time the self-cleaning program is triggered. The gear motor drives the back-flushing turning arm aiming at one filter screen. The upper end of the screen is sealed and the lower end is connected to the cleaning nozzle. And then the cleaning valve opens and connect the screen and discharging pipe. The differential pressure between the filter element’ s outside and discharging nozzle will make the filtrate back-flush the filter screen filter cake dislodged and be purged downward into the sewage pipe.

Positioning device

Positioning disc and cleaning turning arm are installed on the shaft driven by the gear motor. Each positioning hole on the disc matches each screen and cleaning arm is corresponding to one hole. When one hole reaches the channel of positioning sensor the sensor output the signal to stop the gear motor. The cleaning arm has aimed at one element at the same time. The cleaning

valve opens for several seconds till the element is cleaned. Then the gear motor continues rotating. When the next hole on disc reaches the sensor channel the gear motor will stop and the next screen is cleaned.

For more product information please consult technical engineerTel:15216604123

|

Precision Conversion |

Mesh | 300 | 200 | 150 | 120 | 100 | 75 | 60 | 50 | 40 | 35 | 30 | 25 | 20 | 10 | 7 |

| Micron | 50 | 75 | 100 | 125 | 150 | 200 | 250 | 300 | 375 | 500 | 600 | 750 | 1000 | 1500 | 2000 |

| Model No. | AR300/ AR400 /AR500/ AR600/AR700/AR800 /AR900/AR1000 |

| Applicable liquid | Water and low viscous liquids(˂40cps); impurity level˂300ppm |

| Lowest working DP | Differential pressure between the outlet and discharging line >0.15MPa |

| Filter precision | 50-2000μm |

| Design pressure | 0.6/1.0/1.6/2.0MPa(Higher pressure can be customized.) |

| Design temperature | 0-95℃ |

| Single filtering area | 0.45m2-14.40m2 |

| Cleaning Pressure | 0.05-0.1MPa |

| Control system | Parallel control of differential pressure and time |

| DP indicator | Differential pressure transmitter or differential pressure switch |

| Gear motor | Three-phase power 380V protection grade IP55; Turbine worm reducer |

| Inlet and outlet size | 2"-24" |

| Connection Standard | Flange HG20592-2009(Standard) HG20615-2009( ANSI B16.5 Compatible) |

| Filter elements | V-SLOT series slotted screen |

| Filter element material | 316L/Super Duplex Stainless 2205/Ti2 |

| Housing material | 304/316L/CS special material available (such as 904L duplex S.S.) |

| Inner surface anti-corrosion coating | Epoxy PA11 for CS Housing or special anti-corrosion requirement |

| Housing seal material | NBR Nitrile Rubber(Standard)/viton (FKM) fluoro rubber |

| Discharging valve | Pneumatic ball valve protective grade IP65 |

| Facility supply | 380V AC 0.4-0.6MPa Clean and dry compressed air |