Hot sale automatic Self Cleaning Irrigation Bernoulli water filter wi

Your current position:HomeProductAF Series Automatic Self-cleaning FilterHot sale automatic Self Cleaning Irrigation Bernoulli water filter wi

Tel:+86.21 51097921/51090930

Manager Li:13306264360

Technical Support:Mr. Feng 15216602964

Email:jci_sales@163.com

Factory address: 368 Qinggao Road, Fengxian District, Shanghai

AFM series automatic scraper type self-cleaning filter (referred to AFM filter) is a new type of scraper self-cleaning filter with independent intellectual property rights, which automatically removes particulate impurities on the inner surface of the filter through mechanical scraping. The filter precision range is 50-1500 microns. AFM filter can quickly scrape impurities off the surface of the filter screen, effectively removing more impurities. It is suitable for water and various kinds of viscous liquid filtration. AFM filters are designed and manufactured in accordance with our high-performance, high-quality, and high-reliability standards to achieve high quality.

Traditional filters are frequently clogged when filtering viscous materials and soft impurities. Only large filters or frequent manual cleaning can be selected. The investment is large, the workload is heavy, and the material waste is serious. AFM filter can easily solve these problems in a self-cleaning way. It regularly keeps the filter clean and discharges the waste liquid which containing high concentrations of impurities. With its significant technical advantages and low operating costs, AFM filters are gradually replacing traditional manual filters such as vibrating screens, bag filters, basket filters, etc. in many fields.

| Model No. | AFM Series | ||

| Applicable liquid | Water and viscous liquids(˂20,000cps); impurity level˂1,000ppm | ||

| Filter precision | 50-3,000μm | ||

| Design pressure | 0.6-2.5MPa | ||

| Design temperature | 0-260°C(It depends on seals.) | ||

| Single filtering area | 0.14㎡-1.45㎡ | ||

| Cleaning Pressure Drop | 0.05MPa | ||

| DP controller | Differential pressure transmitter or differential pressure switch | ||

| Gear motor | Three-phase power, 380V, protection grade IP55; Turbine worm reducer | ||

| Connection Standard | Flange, HG20592-2009(Standard), HG20615-2009( ANSI B16.5 Compatible) | ||

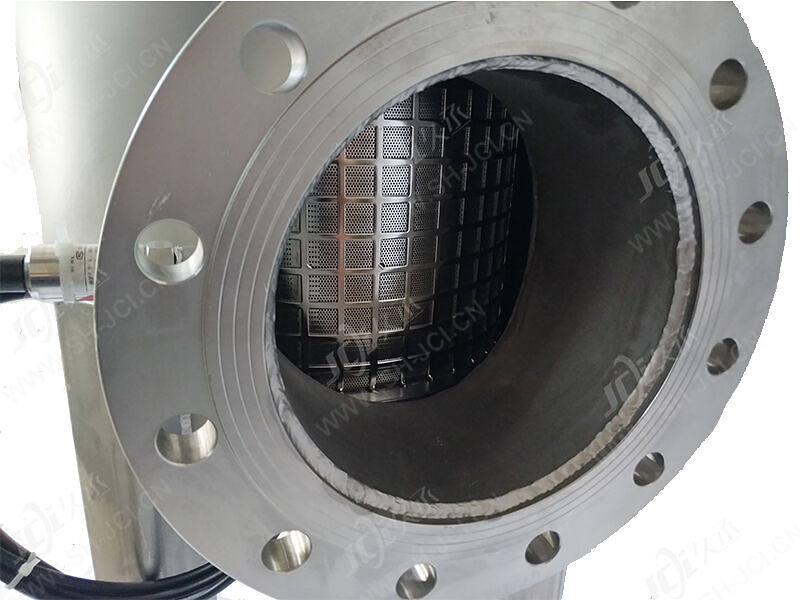

| Filter elements | V-shaped wadge net | ||

| Filter element material | SS304/316L/2205 | ||

| Housing material | SS304/316L/2205/CS | ||

| Scraper material | PTFE | ||

| Housing seal material | NBR Nitrile Rubber(Standard)/viton (FKM) fluoro rubber | ||

| Discharging valve | Pneumatic ball valve, protective grade IP65 | ||

| Facility supply | 380V AC, 0.4-0.6MPa Clean and dry compressed air | ||

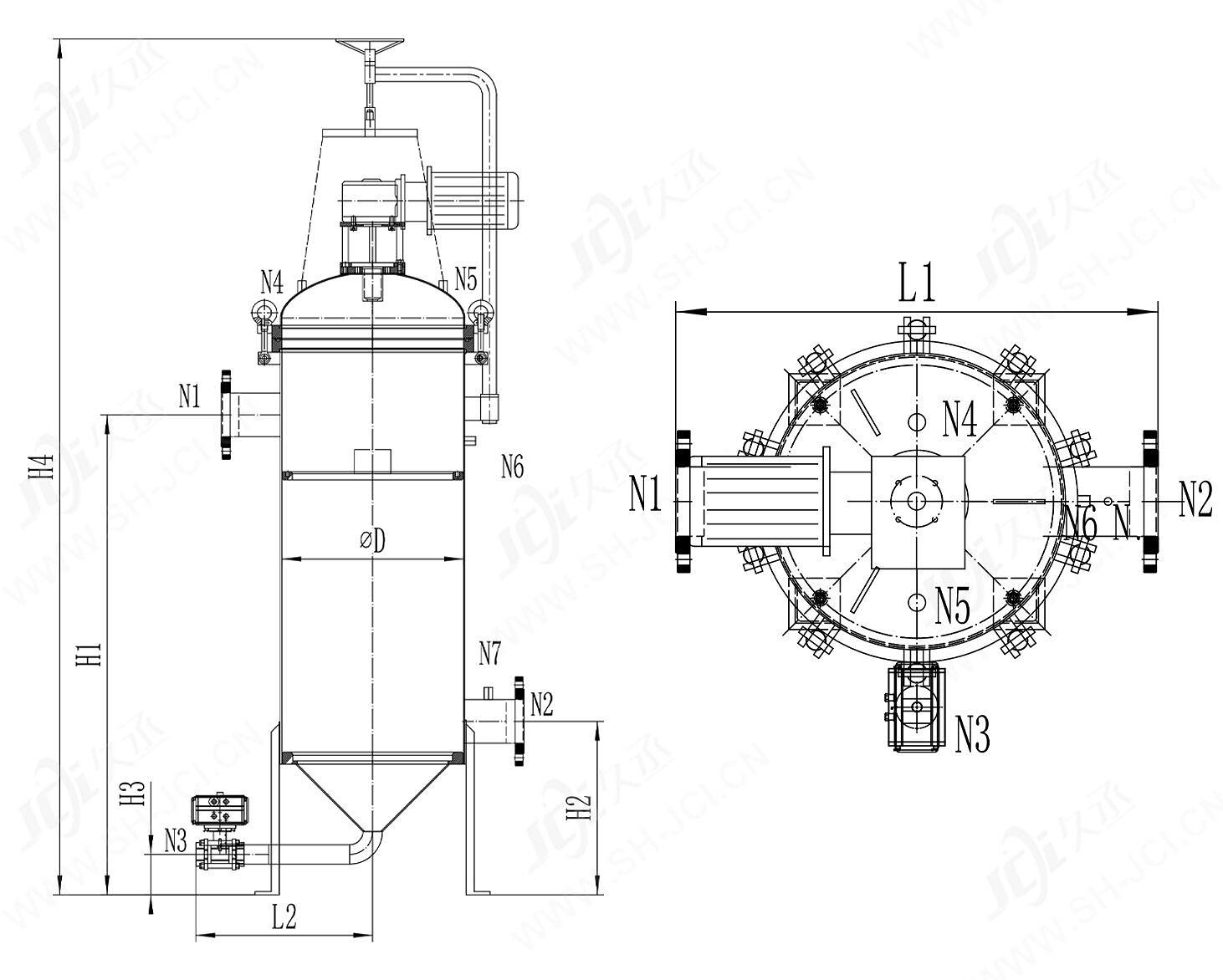

Outline drawing and dimensions:

| ITEM NO. | Nominal diameter of inlet and outlet | Dimention | |||||

| H1 | H2 | H3 | H4 | D | L | ||

| AFM14 | DN32~DN50 | 500 | 270 | 100 | ≈950 | 273 | 450 |

| AFM28 | DN40~DN65 | 760 | 320 | 100 | ≈1270 | 273 | 480 |

| AFM42 | DN40~DN80 | 980 | 335 | 100 | ≈1500 | 273 | 500 |

| AFM77 | DN50~DN100 | 1190 | 430 | 100 | ≈2050 | 450 | 650 |

| AFM116 | DN50~DN125 | 1400 | 525 | 140 | ≈2150 | 550 | 800 |

| AFM145 | DN65~DN150 | 1650 | 540 | 143 | ≈2600 | 550 | 800 |

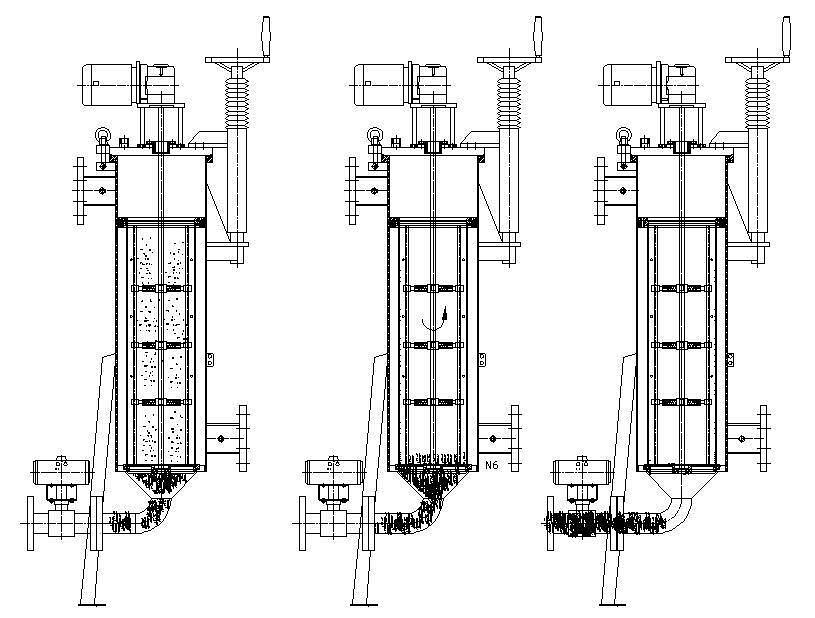

[Filtering status]

The liquid flows in from the inlet, the scraper with compensation is close to the inner surface of the filter, the liquid flows from the inner surface of the filter element through the filter, the impurities are trapped on the inner surface, and the liquid flows out from the outlet; as time goes by, the impurities gradually Increase, the pressure difference rises, according to the set pressure difference or regularly clean the filter screen.

【Cleaning state】

The motor drives the scraper to perform a horizontal rotation to clean the filter screen. When the scraper rotates, the impurities are scraped off by the scraper and flow to the bottom of the filter along the filter screen, and the impurities with large specific gravity settle into the dirt collection chamber. Each cleaning consists of several strokes. After the surface of the filter is cleaned, the filtering capacity is restored. Normally filter during cleaning without interruption of flow.

【Sewage discharge state】

After multiple cleaning cycles, the impurities have accumulated to a sufficient amount, and the drain valve is opened regularly to discharge the waste liquid with high concentration of impurities. If necessary, it can also be recycled.

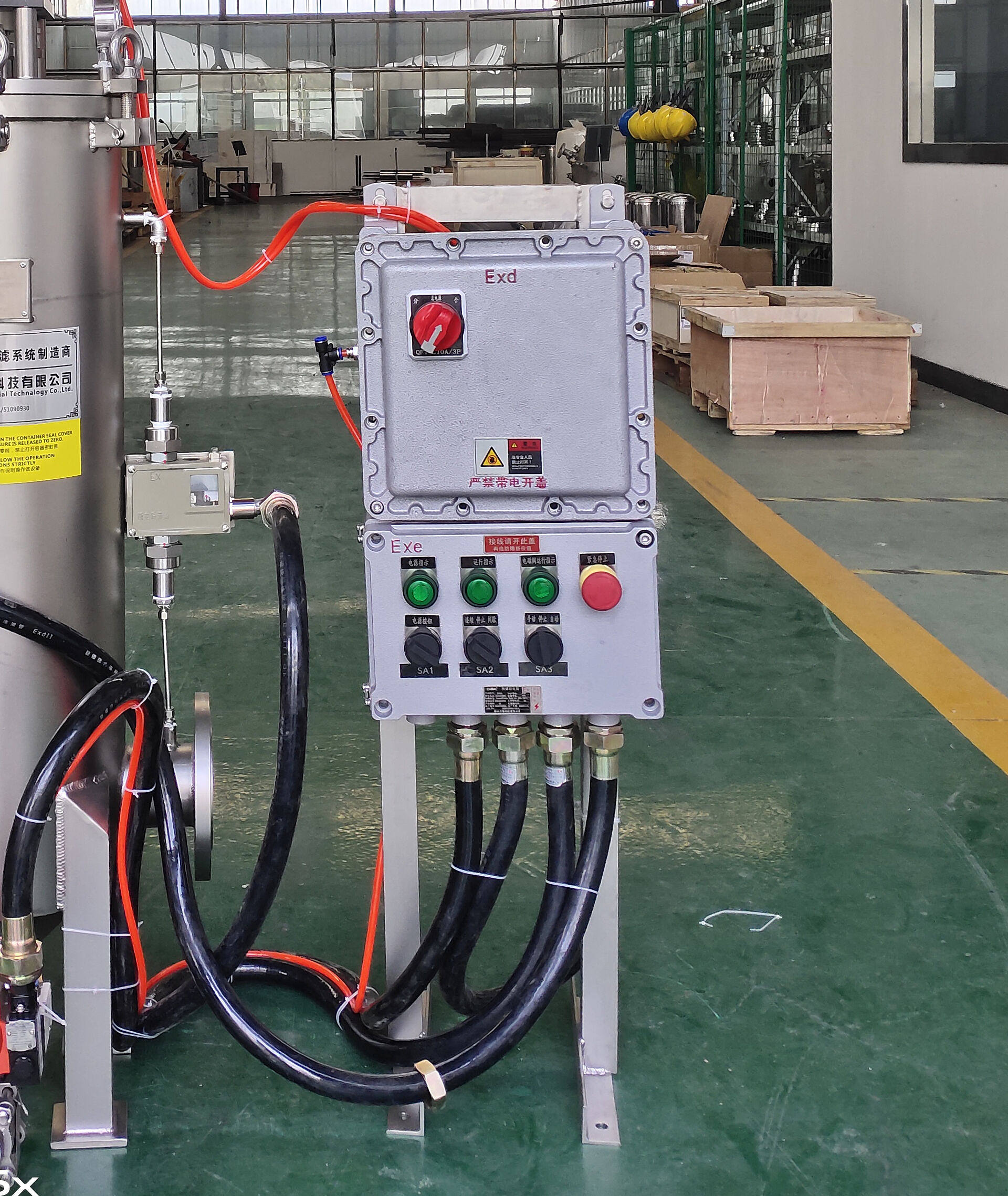

Automatic cleaning control system

AFM filter is equipped with automated cleaning control system, integrated differential pressure cleaning and timing cleaning parallel control function, which controls its efficient working, according to the operating conditions. If necessary, the system is able to realize real-time and remote monitoring of DCS by custom. Differential pressure cleaning is the most efficient cleaning mode, which reflects the accumulation of filter cakes and the blocking of the filter element. When the preset pressure differential is reached, it starts the self-cleaning action. It is suggested that the cleaning pressure differential is 0.1MPa, which can be adjusted within the scope of 0.01-0.1MPa, by the working conditions. Periodically cleaning can be set 0-24 hours, and if the pressure differential mode is inefficient, time pattern still works. It can be considered as the ultimate protection. The cleaning period setting should be close to the average period of the filter pressure differential cleaning mode. The automated differential pressure controller has two kinds of forms, differential pressure switch and differential pressure transmitter. The transmitter can output the real time pressure differential value with higher sensitivity and reliability, to facilitate long-distance and real-time monitoring of the DCS.

Horizontal rotary scraping, scraping away impurities directly, good at filtering viscous liquids, removing viscous soft and suspended impurities.

Simple structure, easy to disassemble and assemble. After removing the scraper, the filter can be easily taken out, and the inside is easy to clean.

Fully automatic operation, continuous online filtration, and stop the heavy filter replacement and cleaning work.

No disposable filtering consumables are generated, saving consumables costs and environmental protection costs.

The filtration pressure loss is extremely small, the flow rate is stable, energy consumption is saved, and the process is continuous and stable.

Airtight filtration to prevent leakage of hazardous materials, which is beneficial to safe production and employee health.

The discharged waste liquid has a high impurity concentration and can be recycled, reducing the loss of high-value materials.

A variety of control systems are optional, powerful, high-energy operation, high reliability.

Optional components, high reliability, low operating cost.

Applicable fields: petrochemical, fine chemical, grease, water treatment, papermaking, etc.

Applicable liquid types: resin, paint, polymer, adhesive, citric acid, fermentation broth, chitosan, cosmetics, agarose (gel), silicone resin solution, soap, sorbitol, steroid, grain syrup, wet Department of additives, pigments, lubricants, rubber, ethanol, mixed oil, edible oil, high temperature oil, fruit juice, diesel, etc.

Cases