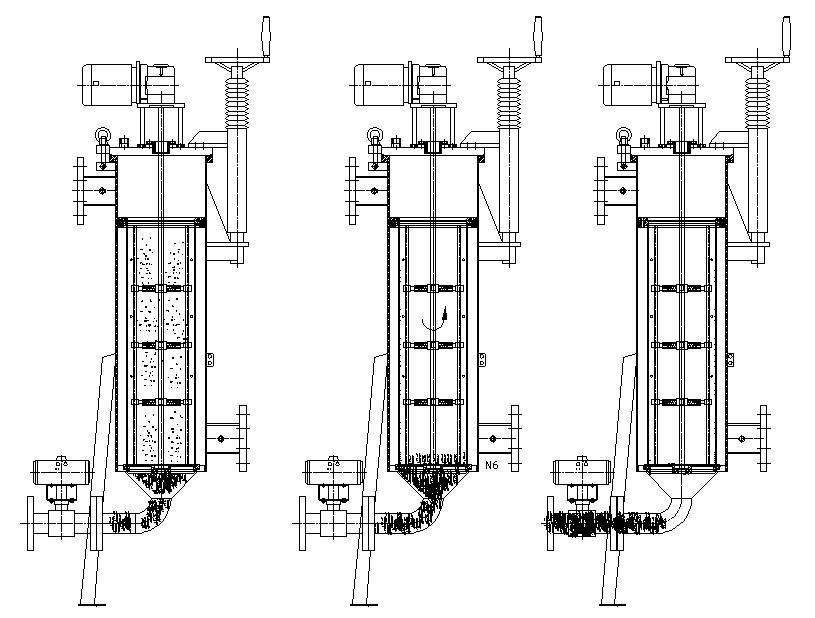

AFB electric brush self-cleaning filter

Your current position:HomeProductAF Series Automatic Self-cleaning FilterAFB electric brush self-cleaning filter

Tel:+86.21 51097921/51090930

Manager Li:13306264360

Technical Support:Mr. Feng 15216602964

Email:jci_sales@163.com

Factory address: 368 Qinggao Road, Fengxian District, Shanghai

Accumulation of of filter cakes and the blocking of the filter element. When the preset pressure differential is reached, it starts the self-cleaning action. It is suggested that the cleaning pressure differential is 0.1MPa, which can be adjusted within the scope of 0.01-0.1MPa, by the working conditions. Periodically cleaning can be set 0-24 hours, and if the differential mode is inefficient, time pattern still works. It can be considered as the ultimate protection. The cleaning period setting should be close to the average period of the filter pressure differential cleaning mode.

Accumulation of of filter cakes and the blocking of the filter element. When the preset pressure differential is reached, it starts the self-cleaning action. It is suggested that the cleaning pressure differential is 0.1MPa, which can be adjusted within the scope of 0.01-0.1MPa, by the working conditions. Periodically cleaning can be set 0-24 hours, and if the differential mode is inefficient, time pattern still works. It can be considered as the ultimate protection. The cleaning period setting should be close to the average period of the filter pressure differential cleaning mode.| Applicable liquid | Water and viscous liquids(˂800,000cps); impurity level˂1,000ppm |

| Filter precision | 30-1500μm |

|

Design pressure |

1.0MPa(Higher pressure can be customized.) |

|

Design temperature |

0-200°C(It depends on seals.) |

|

Single filtering area |

0.14m2-1.45m2 |

|

Cleaning Pressure Drop |

0.05MPa |

|

DP controller |

Differential pressure transmitter or differential pressure switch |

|

Gear motor |

Three-phase power, 380V, protection grade IP55; Turbine worm reducer |

|

Connection Standard |

Flange, HG20592-2009(Standard), HG20615-2009( ANSI B16.5 Compatible) |

|

Filter elements |

V-shaped wadge net/ sintered mesh |

|

Filter element material |

304/316L/2205/Titanium |

|

Housing material |

304/316L/CS |

|

Brush material |

Nylon/stainless steel |

|

Housing seal material |

NBR Nitrile Rubber(Standard)/viton (FKM) fluoro rubber |

|

Discharging valve |

Pneumatic ball valve, protective grade IP65 |

| Facility supply | 380V AC, 0.4-0.6MPa Clean and dry compressed air |

| Filter main model | AFB14 | AFB28 | AFB42 | AFB77 | AFB116 | AFB145 |

| Filtering area (m2) | 0.14 | 0.28 | 0.42 | 0.77 | 1.16 | 1.45 |

| Import and export size | DN20-DN50 | DN50-DN80 | DN50-DN100 | DN65-DN100 | DN80-DN125 | DN100-DN150 |

| Outlet size | DN40 | DN40 | DN50 | DN50 | DN50 | DN50 |

| Cylinder diameter | 273 | 273 | 273 | 460 | 550 | 550 |